Your tools are your lifeline in the precision manufacturing business. CNC machine businesses spend a lot of money on BT40 tool holders and cutter heads. But too often, we find these precise tools left on open benches, stuffed in drawers, or put on shelves that aren’t strong enough to hold them.

If you really want to cut costs and boost productivity, you need to upgrade your storage system.

This guide explores everything you need to know about selecting the right BT40 Cutter Head Storage Rack & Tool Cabinet, focusing on how to protect your expensive cutters and streamline your workshop efficiency.

1. The Hidden Cost of Poor Tool Storage

Before we dive into the features of a premium BT40 Cutter Head Storage Rack & Tool Cabinet, it is crucial to understand the problem. Why isn’t a standard shelf enough?

- Precision Damage: BT40 tapers are ground to exact tolerances. Even minor dings or scratches from metal-on-metal contact can cause “runout” (wobble) in the spindle. This leads to poor surface finishes, broken cutting tools, and eventually, expensive spindle repairs.

- The “Search and Rescue” Time Waste: In a busy shop, time is money. If a machinist spends 10 minutes a day looking for a specific face mill or collet chuck, that adds up to over 40 hours of lost production time per year per employee.

- Contamination Risks: Dust, coolant residue, and metal chips settling on tool tapers can ruin the fit between the tool and the machine.

A dedicated BT40 Cutter Head Storage Rack & Tool Cabinet solves these problems by providing a clean, organized, and protective environment.

2. Core Feature: The Rubber Tool Sheath Technology

Referring to the high-quality designs available in the market (like the one shown in our product catalog), the most critical component of a BT40 Cutter Head Storage Rack & Tool Cabinet is the interface between the cabinet and the tool.

You should strictly avoid bare metal holes. Instead, look for cabinets equipped with ABS or Rubber Tool Sheaths.

Why the “Wavy Texture Design” Matters

As seen in premium models, the tool sheaths often feature a specialized rubber construction with a wavy texture.

- Shock Absorption: When a heavy facemill is dropped into the slot, the rubber absorbs the impact, protecting the delicate taper of the BT40 holder.

- Stable Grip: The texture ensures the tool sits vertically and doesn’t rotate or rattle when the cabinet doors are opened or closed.

- Oil and Corrosion Resistance: High-quality industrial rubber is resistant to cutting fluids and oils, preventing the plastic from becoming brittle over time.

Pro Tip: Never compromise on the inserts. They are the primary defense line for your tooling investment.

3. Anatomy of the Perfect BT40 Cabinet: What to Look For

When evaluating a BT40 Cutter Head Storage Rack & Tool Cabinet, consider these structural elements to ensure longevity and utility.

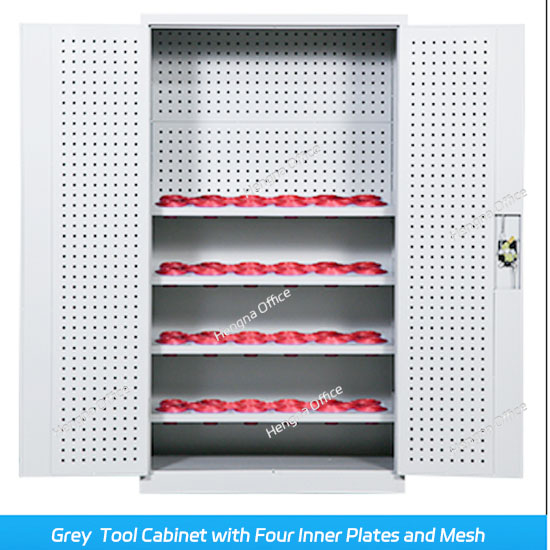

Heavy-Duty Cold Rolled Steel Construction

CNC tools are heavy. A fully loaded rack of 40-50 BT40 holders can weigh hundreds of pounds. The cabinet must be constructed from thickened cold-rolled steel to prevent sagging or structural failure. Look for electrostatic powder coating (often in grey or blue) which provides resistance against rust and shop chemicals.

Capacity and Modularity

A standard high-efficiency cabinet typically features multiple inner plates (shelves).

- Layering: Look for models with 4 to 5 horizontal layers.

- Density: Ensure the spacing allows for the diameter of your largest tools (like large facemills) without them touching each other.

- Adjustability: Can the shelves be moved up or down? This is vital if you have extra-long boring bars or drills.

Smart Door Usage (Pegboards/Mesh)

Don’t waste the vertical space on the doors. The best BT40 Cutter Head Storage Rack & Tool Cabinet utilizes the inside of the doors.

- Hanging Mesh/Pegboard: This allows you to hang wrenches, pull studs, cleaning cloths, and setup sheets right next to the tools.

- Ventilation: Mesh designs can also help with airflow, reducing humidity buildup inside the cabinet which can lead to rust.

4. Implementing “5S” in Your CNC Shop

The “5S” methodology (Sort, Set in order, Shine, Standardize, Sustain) is the gold standard for manufacturing efficiency. Your BT40 Cutter Head Storage Rack & Tool Cabinet is the central hub for this system.

Visual Management

By arranging tools logically in the rack—for example, grouping all drill chucks on the bottom shelf and finishing end mills on the top—you create a visual system. A manager can walk past and instantly see if a tool is missing or if a damaged tool has been returned.

Reduced Setup Times

When a job changeover happens, the operator goes to the cabinet. Because every slot is dedicated, they grab exactly what they need in seconds. This reduction in setup time directly increases your spindle uptime and profitability.

5. Comparison: Standard Shelving vs. Dedicated BT40 Cabinets

To help you make an informed decision, here is a comparison of using generic storage versus a specialized solution.

| Feature | Standard Metal Shelving | Specialized BT40 Tool Cabinet |

| Tool Protection | Low (Tools sit on flat surfaces, risk rolling) | High (Individual rubber sheaths secure each tool) |

| Organization | Poor (Cluttered, hard to find items) | Excellent (Fixed rows, visual inventory) |

| Space Efficiency | Low (Wasted vertical space) | High (High-density vertical storage) |

| Cleanliness | Open to dust and chips | Enclosed design keeps tools clean |

| Load Bearing | Variable (Often sags under weight) | Heavy-duty designed for concentrated weight |

6. Installation and Maintenance Tips

Once you have purchased your BT40 Cutter Head Storage Rack & Tool Cabinet, proper setup will ensure it lasts for decades.

- Leveling: Ensure the cabinet is perfectly level on your shop floor. Uneven flooring can cause doors to misalign over time.

- Weight Distribution: Always load the heaviest tools (large diameter facemills) on the bottom shelves to maintain a low center of gravity and prevent tipping.

- Regular Cleaning: Once a month, vacuum out the rubber sheaths. Metal chips from the machine can sometimes migrate into the cups; cleaning them prevents these chips from scratching the tool tapers.

A BT40 Cutter Head Storage Rack & Tool Cabinet is not just “furniture” for your workshop; it is an asset management tool. By preventing a single spindle crash caused by a damaged tool holder, or by saving just 15 minutes of labor per day, the cabinet pays for itself in a matter of months.

Don’t let your precision tools degrade in a pile on a workbench. Organize your shop, protect your assets, and signal to your customers that you care about quality by investing in professional storage solutions.

Ready to organize your workshop? Browse our full range of CNC storage solutions and find the perfect cabinet for your needs today.

FAQ (Frequently Asked Questions)

Q: Can this cabinet store BT30 or BT50 tools? A: Most cabinets are modular. While the frame is standard, the plastic/rubber inserts are specific to the tool taper. You must specify if you need BT30, BT40, or BT50 inserts when ordering, or check if the inserts are interchangeable.

Q: What is the load capacity of the BT40 Cutter Head Storage Rack & Tool Cabinet? A: High-quality industrial cabinets are designed to hold significant weight, often exceeding 100kg per shelf. However, always check the specific technical parameters of the model you are buying.

Q: Why are rubber sheaths better than plastic ones? A: Rubber sheaths (often ABS mixed or pure rubber) offer better grip and impact resistance. They are less likely to crack under the weight of heavy tools compared to brittle, cheap plastic.