For a CNC machining facility, precision isn’t just a requirement for the final part—it’s a mindset that should extend to every square inch of the shop floor. When your clients need storage solutions that can organize high-value CNC tooling, maximize space in a cramped machine shop, and survive the daily abuse of a heavy-industrial environment, they quickly realize that standard office-grade cabinets simply won’t cut it.

How to Choose the Right OEM Partner for Custom CNC Tool Storage and Workshop Furniture?The gap between a “standard metal box” and a “precision-engineered tool station” is where the value of a professional OEM partner lies. But in a global market flooded with suppliers, how do you distinguish a reliable manufacturer from a middleman who simply undercuts on price?

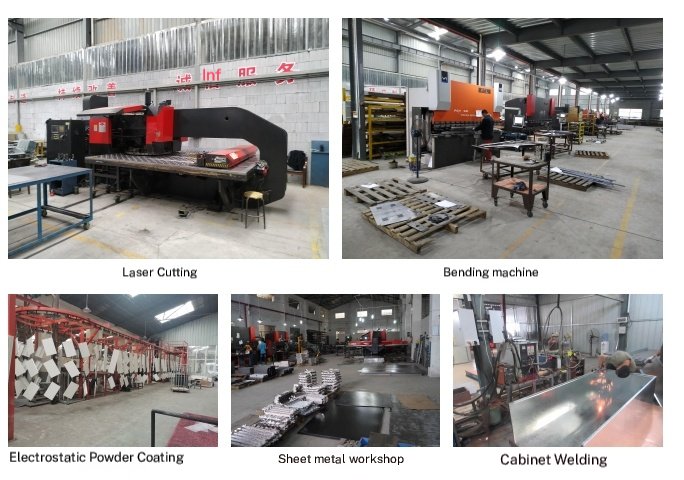

As a manufacturer with 15 years of specialized experience in industrial storage—Luoyang Hengna Office Furniture Co., Ltd.—we’ve handled thousands of export orders. We’ve seen the frustrations of international buyers who chose the lowest bid only to deal with collapsed drawers and seized slides. Based on our 15 years on the shop floor, here is a deep dive into the criteria that truly matter when selecting an OEM partner for your workshop furniture line.

1. Technical Literacy: Do They Understand the “Physics” of a Machine Shop?

Many generalist furniture factories can bend sheet metal and spray it with paint. However, very few understand the specific stress points of a CNC tool rack. A single BT40 or HSK63 tool holder might not seem heavy, but when you load 30 of them into a single drawer, the physics of the cabinet changes entirely.

A qualified OEM partner should talk to you about static vs. dynamic load capacities. At our facility in Luoyang, we don’t just “guess” at the strength of a cabinet. We understand that:

- Slide Integrity: For heavy-duty tool carts, standard ball-bearing slides are insufficient. We utilize triple-extension, full-pullout cold-rolled steel slides. This ensures the user can access tools at the very back of the drawer without the drawer sagging or the cart tipping.

- Reinforcement: A professional CNC cabinet needs integrated “ribs” or U-shaped reinforcements under each drawer and at the base.

- Tool Protection: CNC tools are precision instruments. A good OEM partner will offer specialized ABS tool inserts or oil-resistant liners that prevent metal-on-metal contact, protecting the tool shanks from micro-scratches that could affect machining accuracy.

2. The “Small Batch” Reality: Reducing Your Market Entry Risk

In the B2B world, the “Large Factory Trap” is real. Many massive manufacturers will only talk to you if you’re ordering 500+ units. For a distributor testing a new private label or a niche design for a specific regional market (like the North American or European machine shop sectors), this creates an impossible barrier to entry.

We’ve built our production model at Hengna to be flexible and responsive. We accept trial orders of 50 to 100 units. Why? Because we know that industrial buyers value quality over flash. We would rather help you launch a successful product line with 50 perfect units that sell out quickly, than force you to warehouse 500 units that might need minor tweaks for the next version. This “Scale-as-you-Grow” approach builds trust and allows you to gather real-world feedback from your end-users before committing to high-volume production.

3. Direct Engineering Communication: No “Middleman” Friction

One of the biggest headaches for overseas buyers is the “lost in translation” effect. When you work through a trading company, your technical requirements are filtered through a salesperson who may have never seen a CNC machine in person.

By partnering directly with a factory like Hengna, you are in a direct loop with the production engineers. We provide:

- Technical CAD Drawings: Every customization is documented. We don’t start production until the drawing—down to the millimeter—is approved by you.

- Detailed BOM (Bill of Materials): You will know exactly what gauge of steel is being used, the brand of the lock mechanism, and the micron thickness of the powder coating.

- Transparent Quality Control: We share QC reports and real-time photos of the production line. If there is a material delay or a technical challenge, we tell you immediately and provide a solution. In the B2B sector, honesty about lead times is worth more than a broken promise of “speed.”

4. Beyond Private Labeling: The Depth of “Real” Customization

Private labeling (putting your logo on a standard item) is the bare minimum. True OEM partnership involves structural and functional adaptation to meet specific market demands.

Your clients might have unique pain points. For example:

- Height Requirements: In some markets, taller tool carts are preferred for ergonomic reasons.

- Specialized Storage: Maybe your customers use extra-long boring bars that don’t fit in standard drawers. We can modify the “Step-type” drawer configuration to accommodate specific tool lengths.

- Environment-Specific Finishes: If the workshop environment is particularly humid or uses corrosive coolants, we can pivot from standard powder coating to 304 stainless steel or specialized anti-corrosive treatments.

- Integration: We can pre-drill mounting holes for tablet holders, document stations, or power strips, turning a simple cabinet into a modern “Smart Workstation.”

5. The Long-Term ROI: Durability vs. The “Low-Price” Trap

It is easy to make a tool cabinet look good in a catalog photo. It is much harder to make it look and function the same way after three years of being pushed across a concrete floor and slammed shut by workers wearing heavy gloves.

The “Total Cost of Ownership” is a concept your B2B clients care about. A cheap cabinet that warps under load isn’t just a waste of money—it’s a safety hazard. We focus on industrial-grade longevity. Our 15 years of experience have taught us where the “hidden” costs are. By using high-quality cold-rolled steel and a multi-stage pickling and phosphating process before powder coating, we ensure our cabinets don’t rust or peel, even in oily workshop environments.

Partner with a Manufacturer That Knows the Shop Floor

At Luoyang Hengna Office Furniture Co., Ltd., we don’t just manufacture furniture; we build the infrastructure that keeps industrial operations organized and efficient. We are looking for global B2B partners—distributors, wholesalers, and brand owners—who are tired of “disposable” industrial furniture and are ready for a grounded, technical partnership.

We offer:

- Expertise in Custom CNC Tool Carts, Heavy-Duty Workbenches, and Modular Storage.

- Low-risk small-batch prototyping and trial orders.

- Direct access to factory-level engineering support.

If you have a project in mind or a client request that standard suppliers can’t fulfill, let’s talk. Provide us with your basic requirements, and our team will provide a professional proposal with specific component parameters.

Stop settling for “Standard.” Start building “Purpose-Built” storage today.