15

2025 - 12

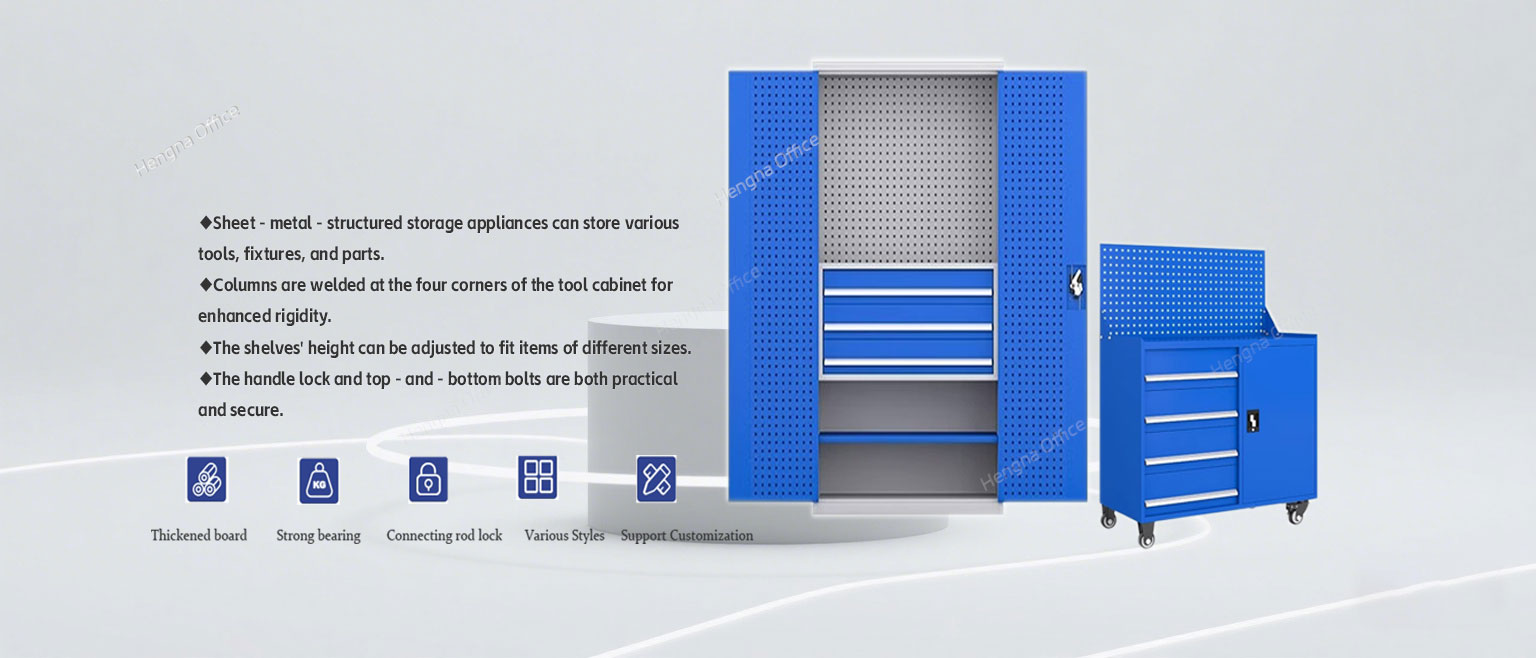

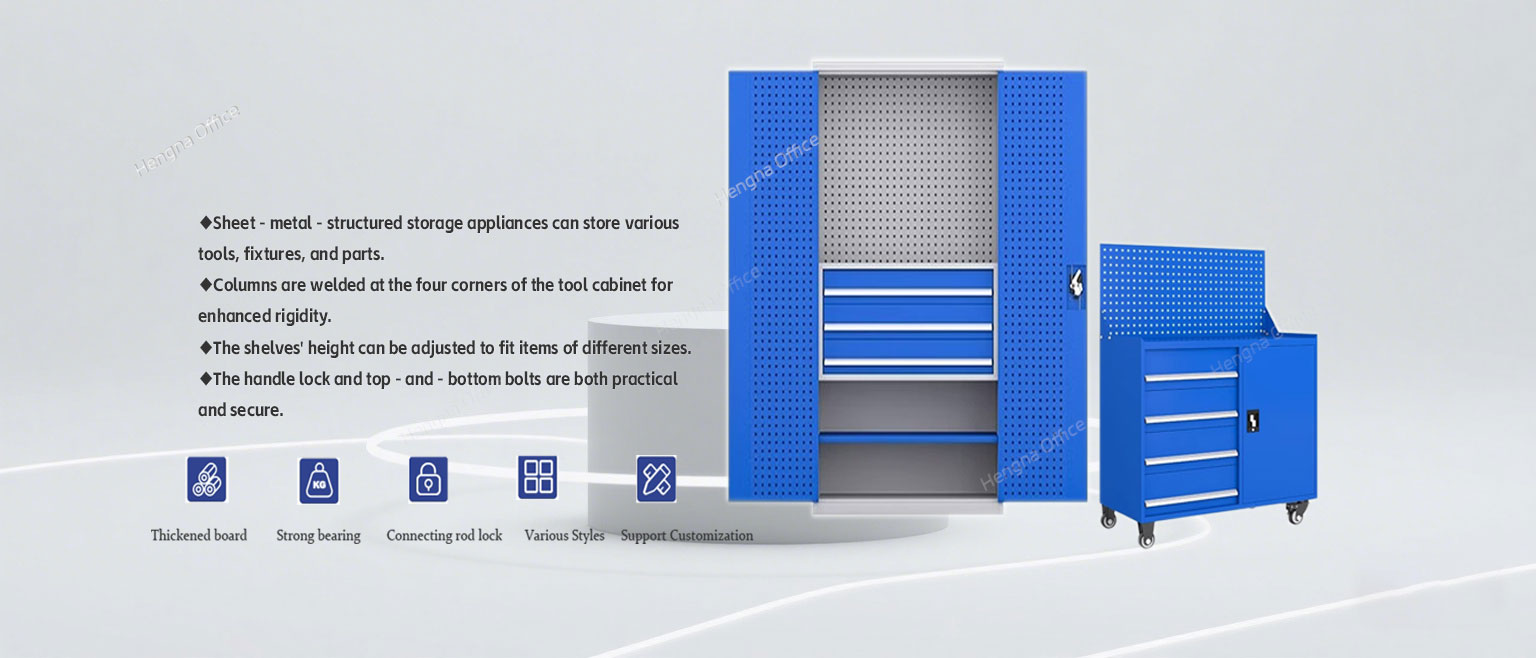

In today’s factories, how well tools and parts are managed has a big effect on how productive they are. When technicians have trouble finding equipment or spare parts, downtime goes up, processes slow down, and overall operational efficiency goes down. This is why more and more places are using steel pegboard tool racks, especially the heavy-duty single-sided and double-sided ones that are utilized in automobile manufacturers, machining shops, warehouse maintenance departments, and industrial production lines. These racks help teams keep things organized, keep tools safe, and get to them quickly, which helps them get rid of clutter and keep operations running smoothly. In this post, we talk about the main benefits of steel pegboard tool racks and how they make production environments more productive. 1. Solving the Most Common Tool Management Problems Before introducing pegboard tool racks, many manufacturing plants face the same issues: Common Issues (Visual Table Format) Problem Impact on Workflow Tools piled randomly and hard to find Increased downtime, delayed repairs Tools placed anywhere, wasting workspace Unsafe and inefficient environment Too many tool types, no structured storage Confusion and frequent misplacement Toolboxes too small to hold large tools Overfilling, tool damage, slow access These challenges often appear…