17

2026 - 01

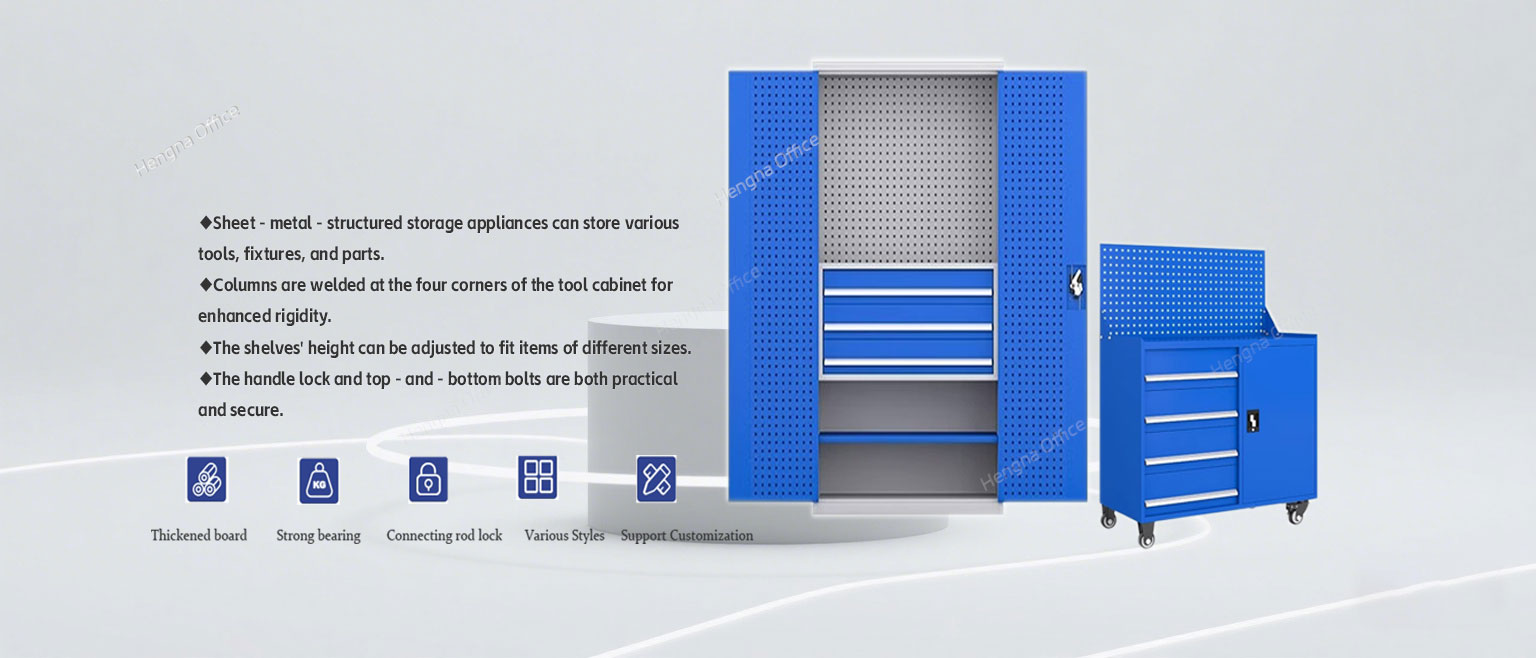

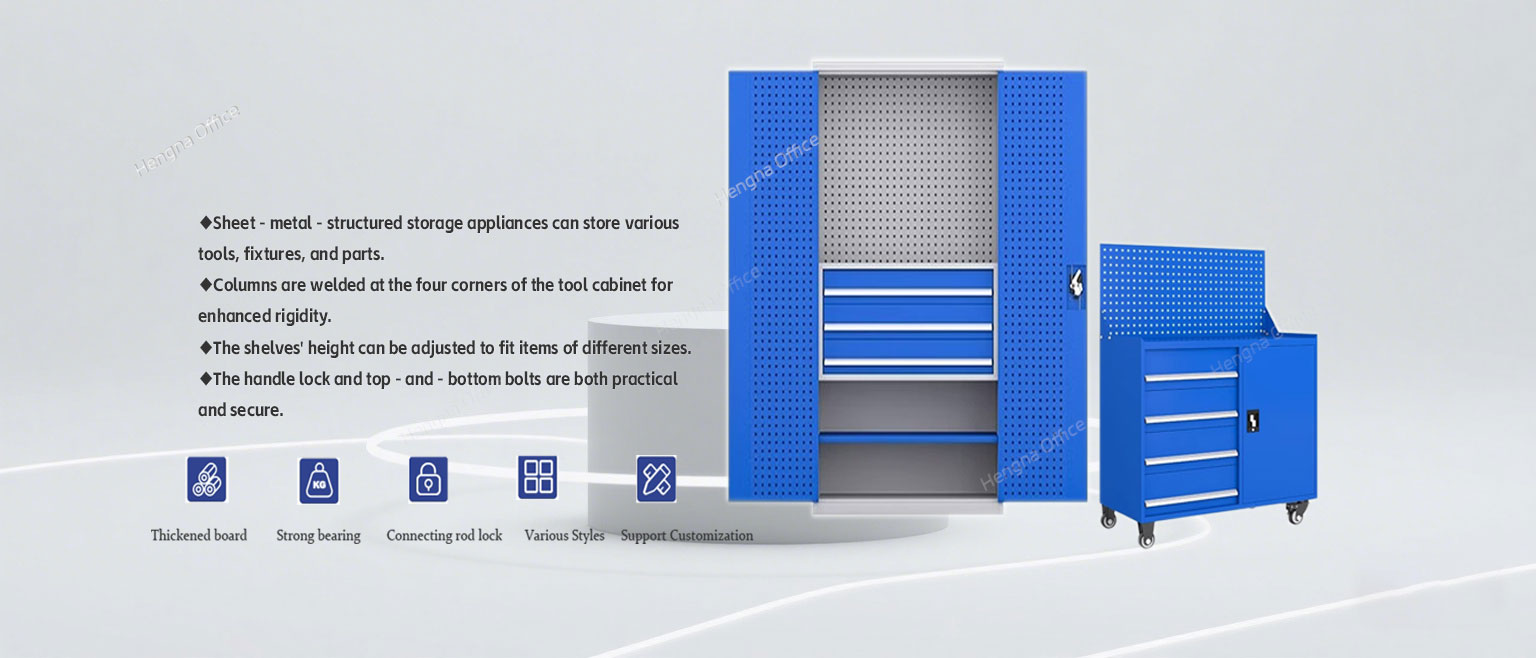

In high-velocity logistics and manufacturing, operational throughput is the definitive measure of success. As traditional warehouses transition into high-tech fulfillment hubs, legacy static tables have become a primary constraint on assembly and repair cycles. To meet escalating volume requirements, we are shifting toward a more agile infrastructure: Modular Workbenches with Integrated Tool Storage. But why is this shift happening now? And how exactly does a piece of furniture become a “game-changer” for your bottom line? In this deep dive, we’ll explore how modularity and integrated storage transform chaotic workspaces into streamlined hubs of productivity. The Evolution of the Industrial Workstation For decades, a workbench was just a flat surface. If a worker needed a tool, they walked to a central cabinet. If they needed a specific screw, they searched through a disorganized bin across the room. In lean manufacturing terms, this is known as “Motion Waste.” Every step taken away from the workbench is a second of lost productivity. Modern modular workbenches, such as those featuring L-shaped cantilever uprights, solve this by bringing the entire workshop to the worker. By integrating vertical tool storage and under-desk cabinetry, these stations minimize movement and maximize focus. 1. The Modular Advantage: L-Shaped Cantilever…