11

2025 - 12

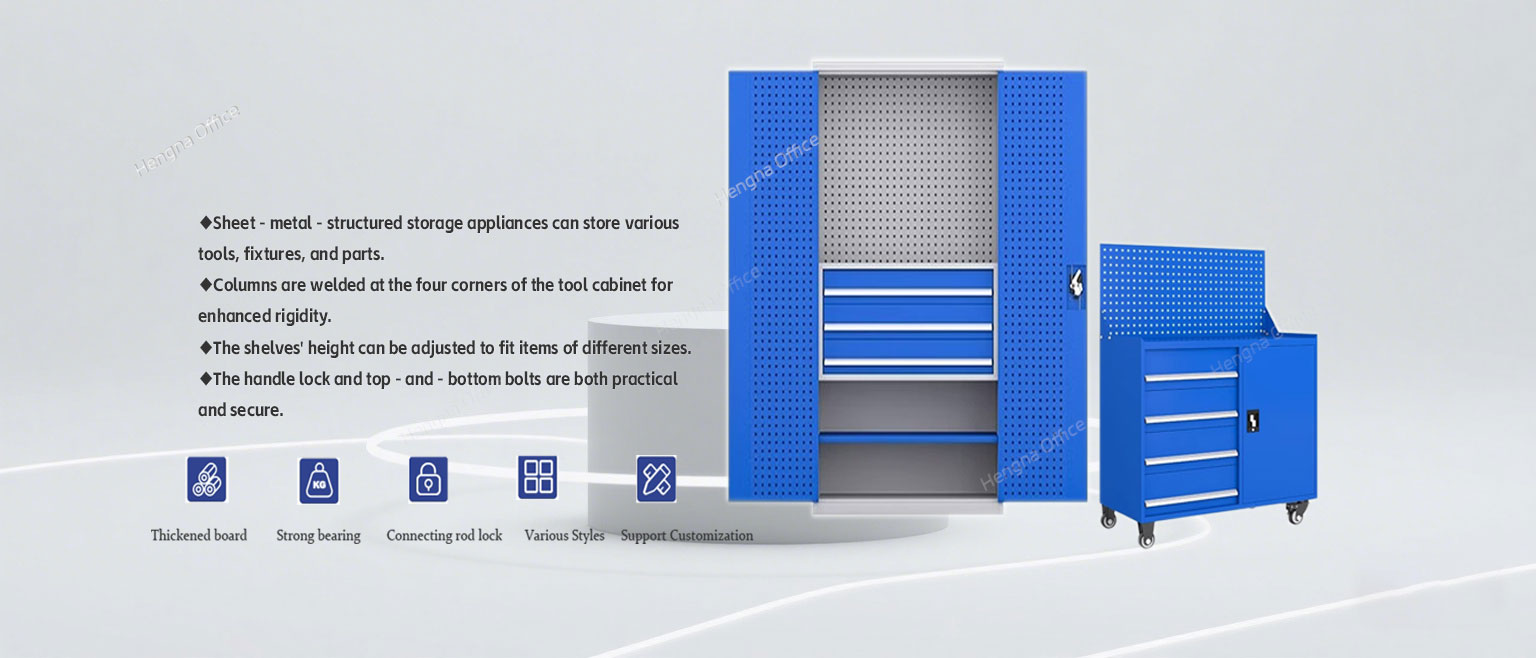

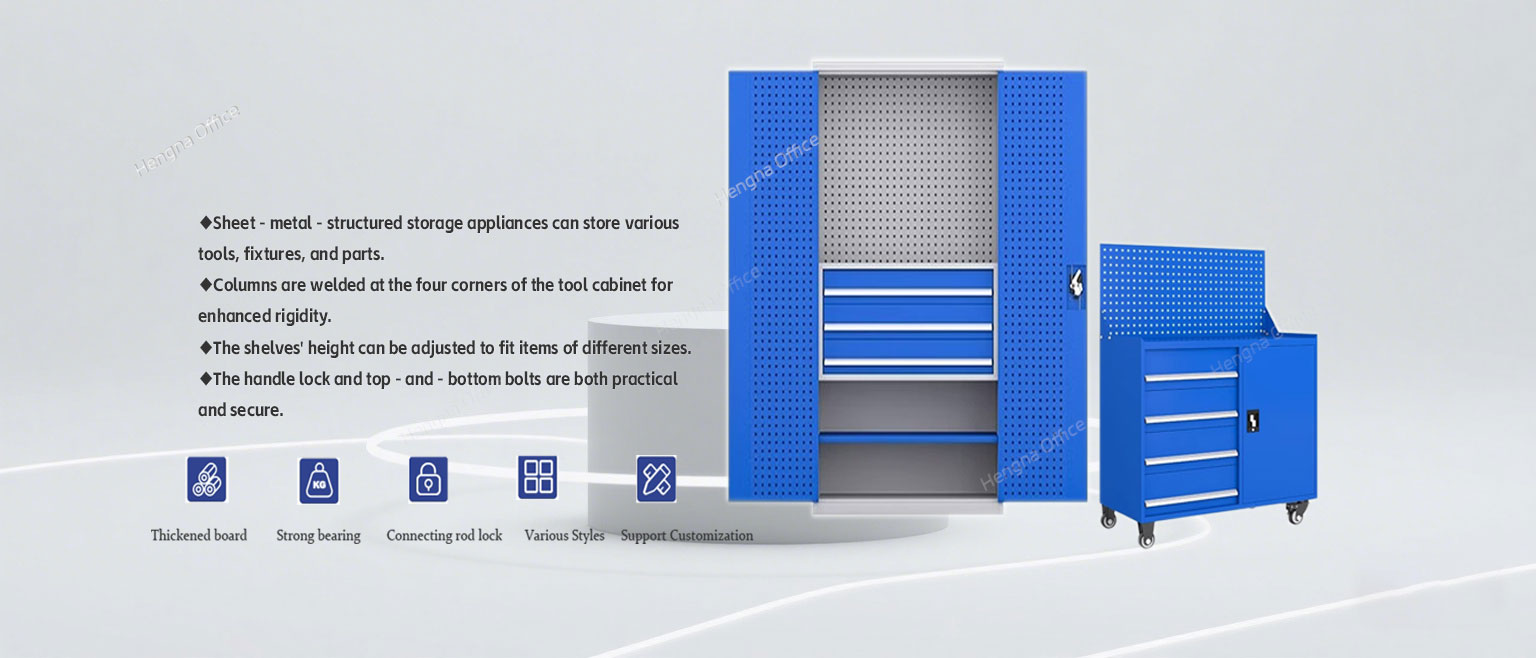

One of the hardest things for maintenance departments in factories, car repair shops, warehouses, and engineering workshops is to keep track of tools and parts. Every second spent looking for tools, spare parts, or fittings lowers productivity and raises downtime. This is why more and more facilities are switching to single-sided tool storage racks. They are a streamlined, space-saving, and highly versatile solution that combines visual management, easy access, and heavy-duty stability. 1. Dual Pegboard System: Designed for Maximum Compatibility One of the key innovations of modern single-sided tool racks is the dual pegboard system. Unlike simple tool boards, this system supports both tools and small parts, making it ideal for maintenance teams who manage a large amount of diverse equipment. ✔ 1.1 Square Hole Pegboard (10×10mm) This standardized format ensures that procurement teams don’t need custom hooks, reducing cost and improving compatibility across workshop tools. ✔ 1.2 Louvered Panel for Parts Bins Perfect for small-item management, including: Facilities that follow 5S and Lean Management particularly value the ability to create clear, visual parts storage systems. 2. Flexible Configuration: Fixed or Mobile, Single or Double-Sided Maintenance departments often operate in dynamic environments where tool stations need to adapt to changing…