Introduction to Industrial Tool Storage Evolution

The landscape of industrial tool storage has evolved significantly in response to changing workshop requirements. Among the critical decisions facing facility managers is the selection between tool cabinets with integrated backboards and those without. This analysis examines the functional differences, operational implications, and suitability factors for each configuration, providing objective guidance for storage system selection in professional environments.

Tool Cabinet Comparison: Backboard vs. Non-Backboard Fundamental Design Differences

Tool cabinets with backboards feature a perforated steel panel attached to the rear of the cabinet structure. This panel accommodates various hooks, brackets, and accessories for hanging tools and equipment. Non-backboard models present a solid rear panel, focusing storage capacity exclusively within the drawer system. The backboard configuration transforms the cabinet from a simple storage unit into a comprehensive workstation, while non-backboard designs prioritize contained storage and protection.

Storage Efficiency Analysis

Backboard-equipped cabinets maximize vertical space utilization by providing additional storage surfaces beyond drawer capacity. This configuration allows for immediate access to frequently used tools without drawer operation. Non-backboard models offer superior protection for sensitive tools by enclosing all storage within the cabinet structure. The backboard system typically increases overall storage capacity by 25-30% compared to similarly sized non-backboard units. However, this efficiency comes at the cost of reduced protection from environmental factors such as dust and moisture.

Accessibility and Workflow Considerations

Workflow efficiency differs significantly between the two configurations. Backboard models support rapid tool access for high-frequency operations, reducing time spent opening and closing drawers. This feature proves particularly valuable in assembly line environments or repair stations where specific tools require repeated access. Non-backboard cabinets provide more organized storage for comprehensive tool sets, with each item contained within designated drawer compartments. This configuration minimizes tool misplacement and supports systematic inventory management in environments with extensive tool collections.

Environmental Suitability Factors

Workshop environmental conditions heavily influence the optimal cabinet selection. Backboard models perform best in climate-controlled environments where dust and debris are minimized. The exposed tool hanging system requires regular cleaning to maintain functionality. Non-backboard cabinets excel in harsher industrial settings, providing superior protection against contaminants. The enclosed drawer system safeguards precision tools from environmental factors that could compromise performance or longevity. Facilities with variable environmental conditions often implement a combination of both cabinet types to address different storage requirements.

Space Utilization and Workshop Layout

Spatial constraints significantly impact cabinet selection. Backboard-equipped cabinets require additional clearance space to accommodate tool access from the rear. This configuration works best in open workshop areas with adequate maneuvering space. Non-backboard models offer greater placement flexibility, functioning effectively against walls or in confined spaces. The space-efficient design of non-backboard cabinets makes them preferable for facilities with limited floor area or complex workshop layouts. However, this space efficiency comes at the cost of reduced immediate tool accessibility.

Maintenance Requirements Comparison

Maintenance protocols differ substantially between the two configurations. Backboard models require regular cleaning of the perforated panel and hanging accessories to prevent debris accumulation. The exposed tool hanging system necessitates frequent inspection to ensure secure attachment. Non-backboard cabinets demand less intensive maintenance, focusing primarily on drawer slide lubrication and caster functionality. The enclosed storage system reduces cleaning frequency and extends intervals between maintenance interventions. Facilities with limited maintenance resources often favor non-backboard designs for their reduced upkeep requirements.

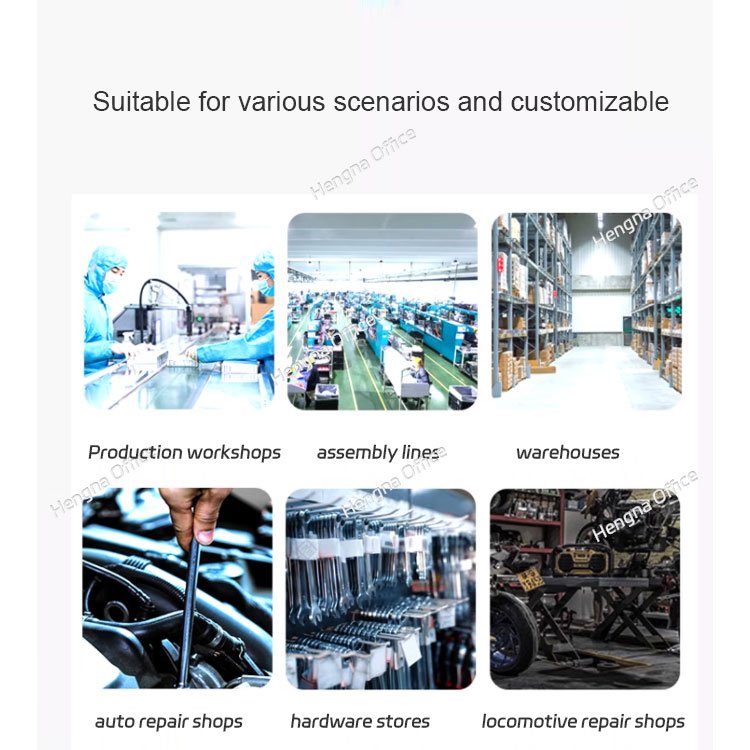

Industry-Specific Recommendations

Different industrial sectors demonstrate distinct preferences based on operational requirements. Automotive repair facilities typically favor backboard-equipped cabinets for immediate access to hand tools during repair procedures. Manufacturing environments with assembly line operations benefit from the rapid tool accessibility provided by backboard systems. Maintenance departments with extensive tool inventories often implement non-backboard cabinets for organized storage and protection of specialized equipment. Educational institutions frequently select non-backboard models for their durability and reduced maintenance requirements in shared-use environments.

Selection Criteria Framework

The optimal cabinet selection depends on four critical factors: tool access frequency, environmental conditions, available space, and maintenance capacity. High-frequency tool access environments benefit from backboard configurations despite their increased maintenance requirements. Harsh environmental conditions favor non-backboard models for their superior protection. Space-constrained facilities should prioritize non-backboard designs for their efficient footprint. Organizations with limited maintenance resources should consider non-backboard cabinets for their reduced upkeep demands.

Conclusion

The selection between backboard and non-backboard tool cabinets represents a critical decision impacting operational efficiency in industrial environments. Each configuration offers distinct advantages suited to specific workshop requirements. Backboard models excel in accessibility and expanded storage capacity, while non-backboard designs provide superior protection and reduced maintenance. Facility managers should evaluate their specific operational needs, environmental conditions, and resource constraints to determine the optimal storage solution. In many cases, a combination of both cabinet types provides the most comprehensive approach to industrial tool management.