In today’s factories, how well tools and parts are managed has a big effect on how productive they are. When technicians have trouble finding equipment or spare parts, downtime goes up, processes slow down, and overall operational efficiency goes down.

This is why more and more places are using steel pegboard tool racks, especially the heavy-duty single-sided and double-sided ones that are utilized in automobile manufacturers, machining shops, warehouse maintenance departments, and industrial production lines.

These racks help teams keep things organized, keep tools safe, and get to them quickly, which helps them get rid of clutter and keep operations running smoothly. In this post, we talk about the main benefits of steel pegboard tool racks and how they make production environments more productive.

1. Solving the Most Common Tool Management Problems

Before introducing pegboard tool racks, many manufacturing plants face the same issues:

Common Issues (Visual Table Format)

| Problem | Impact on Workflow |

|---|---|

| Tools piled randomly and hard to find | Increased downtime, delayed repairs |

| Tools placed anywhere, wasting workspace | Unsafe and inefficient environment |

| Too many tool types, no structured storage | Confusion and frequent misplacement |

| Toolboxes too small to hold large tools | Overfilling, tool damage, slow access |

These challenges often appear in environments such as:

- Automotive repair workshops

- CNC machining and fabrication areas

- Facility maintenance departments

- Assembly line workstations

- Warehouse repair zones

A steel pegboard tool rack directly addresses all these problems, providing a centralized, organized, and accessible storage solution.

2. Superior Organization with a Heavy-Duty Steel Pegboard System

Pegboard tool racks are built around two powerful storage components—square-hole steel pegboards and louvered bin panels.

✔ 2.1 Square-Hole Pegboard (10×10mm Standard)

These industrial-grade pegboards feature:

- Universal compatibility with standard square-hole hooks

- 38 mm hole spacing for balanced weight distribution

- High load capacity for heavy tools

Perfect for organizing:

- Wrenches

- Hammers

- Electric drills

- Screwdrivers

- Pneumatic tools

- Measuring tools

Unlike wooden or plastic pegboards, steel provides the strength required for heavy industrial use.

✔ 2.2 Louvered Panels for Parts Bins

These panels allow the use of stackable, color-coded parts bins, ideal for:

- Screws

- Nuts & bolts

- Electronic components

- Washers

- Machine fittings

This “visual parts management” helps technicians immediately locate small items without digging through drawers.

3. Reduced Downtime Through Faster Tool Access

Manufacturing plants operate under tight schedules where every second counts.

A steel pegboard tool rack significantly reduces downtime by creating:

- Clear tool visibility – nothing is hidden

- Fixed tool positions – each tool has a dedicated spot

- Intuitive layout – technicians can find tools instantly

⏱ Case Example

A technician searching for a missing wrench during a maintenance task may lose 2–5 minutes.

Multiply this by:

- 10 technicians

- 15 searches per day

- 30 working days

This results in over 60 hours of lost productivity per month.

Pegboard tool racks eliminate this loss by providing fast, direct access.

4. Flexible Configuration for Any Industrial Space

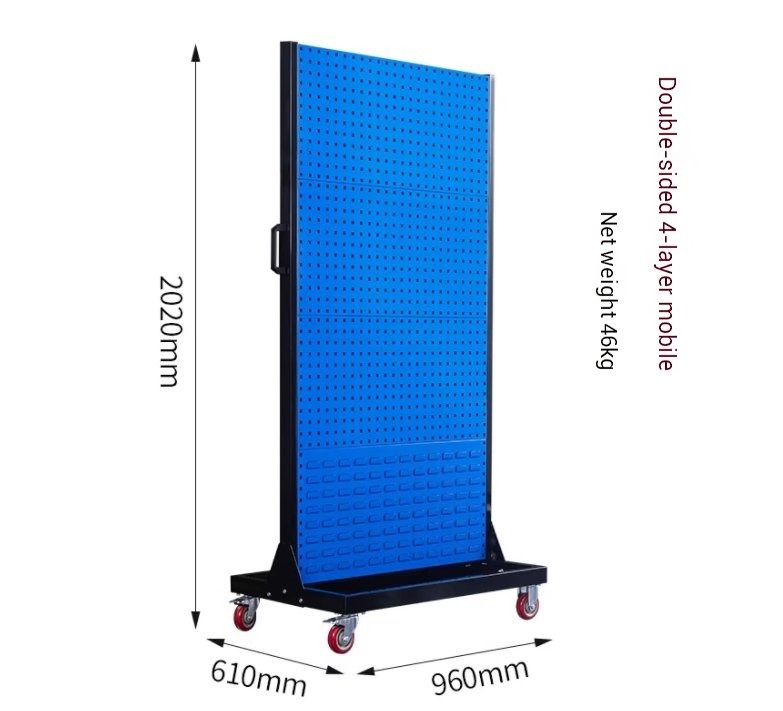

Manufacturing plants vary widely in layout and workflow. Steel pegboard racks are available in multiple designs to meet any space requirement.

✔ 4.1 Single-Sided Racks

Best for:

- Spaces along walls

- Compact workshops

- Tool rooms

✔ 4.2 Double-Sided Racks

Provide:

- 360° storage

- Twice the capacity

- Quick access for multiple technicians

Ideal for:

- Large repair bays

- Shared work zones

- Central tool stations

✔ 4.3 Fixed or Mobile Options

- Fixed base: stable for heavy equipment

- Mobile base with locking casters: easy to reposition across workshops

Mobile models include U-shaped handles, making movement smooth even under full load.

5. Built for Durability: All-Steel Construction

Manufacturing plants require equipment that can withstand daily heavy use.

Steel pegboard tool racks offer industrial-grade strength due to:

✔ Cold-Rolled Steel Frame

- High structural stability

- Smooth coating surface

- Excellent impact resistance

✔ Reinforced Bottom Structure

A triangular steel reinforcement plate increases:

- Load capacity

- Anti-tip stability

- Overall rigidity

✔ Premium Electrostatic Powder Coating

Prevents:

- Rust

- Scratches

- Chemical corrosion

This ensures a long-lasting tool rack that maintains a professional appearance.

6. Supports Lean Manufacturing and 5S Standards

Steel pegboard racks directly support:

- Sort – categorize tools clearly

- Set in Order – fixed positions for each tool

- Shine – easy cleaning and inspection

- Standardize – consistent layouts for all teams

- Sustain – maintain productivity and safety

This makes pegboard racks a key component in lean manufacturing environments.

7. Optional Hooks, Holders, and Accessories for Customization

To meet diverse industrial needs, steel pegboard racks can be equipped with specialized attachments:

Tool Hooks

- Angled hooks (50 / 100 mm)

- U-shaped hooks

- Wrench holders

- Drill holders

- Saw hooks

Parts Bins

- No.1 / No.2 / No.4 back-hanging bins

- Modular combined bins

Special Holders

- Circular ring holders

- Cable brackets

- Tool trays

This customization makes the rack adaptable to almost any production line or maintenance department.

8. Summary Table: Why Manufacturing Plants Prefer Steel Pegboard Racks

| Feature | Benefit | Manufacturing Use |

|---|---|---|

| Steel square-hole pegboard | Heavy-duty tool support | Machining, automotive |

| Louvered parts bins | Fast small-part access | Assembly, electronics |

| Mobile double-sided design | High capacity & flexibility | Large plants |

| Reinforced steel structure | Long lifespan | Harsh industrial environments |

| 5S-friendly layout | Better efficiency & safety | Lean manufacturing |

Steel pegboard tool racks are a tried-and-true way for factories to get more organized, work faster, and cut down on expensive downtime. These racks are a must-have for any modern industrial facility since they are strong, can be set up in many different ways, and work with a wide range of tools and parts.

Plants may make their work easier, encourage lean management, and keep their environment clean, efficient, and professional by using steel pegboard storage solutions.