One of the hardest things for maintenance departments in factories, car repair shops, warehouses, and engineering workshops is to keep track of tools and parts. Every second spent looking for tools, spare parts, or fittings lowers productivity and raises downtime.

This is why more and more facilities are switching to single-sided tool storage racks. They are a streamlined, space-saving, and highly versatile solution that combines visual management, easy access, and heavy-duty stability.

1. Dual Pegboard System: Designed for Maximum Compatibility

One of the key innovations of modern single-sided tool racks is the dual pegboard system. Unlike simple tool boards, this system supports both tools and small parts, making it ideal for maintenance teams who manage a large amount of diverse equipment.

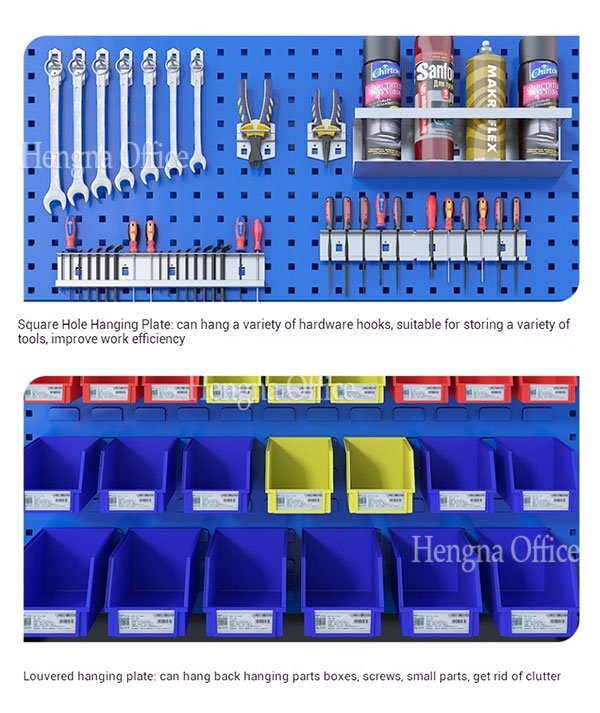

✔ 1.1 Square Hole Pegboard (10×10mm)

- Compatible with most standard square-hole hooks on the market

- Suitable for hanging manual tools

- Supports heavier tools such as drills, wrenches, and electric tools

- 38 mm standard hole spacing ensures even weight distribution

This standardized format ensures that procurement teams don’t need custom hooks, reducing cost and improving compatibility across workshop tools.

✔ 1.2 Louvered Panel for Parts Bins

Perfect for small-item management, including:

- Screws

- Fasteners

- Washers

- Electrical components

- Replacement parts

Facilities that follow 5S and Lean Management particularly value the ability to create clear, visual parts storage systems.

2. Flexible Configuration: Fixed or Mobile, Single or Double-Sided

Maintenance departments often operate in dynamic environments where tool stations need to adapt to changing workflow.

This is why flexibility is a crucial design attribute.

✔ 2.1 Multiple Layouts

- Single-sided wall-hugging type: Ideal for compact workshops or narrow aisles

- Double-sided rack: Freestanding 360° access—popular in large maintenance zones

✔ 2.2 Fixed or Mobile Options

- Standard model: Fixed base for stable long-term use

- Upgraded model: Heavy-duty casters with brakes

This hybrid system allows users to choose between stability and mobility, depending on the application. For example:

- A factory assembly line may require mobile racks to follow technicians along the line

- A tool room or maintenance department may prefer fixed positioning for better inventory control

The mobile version also includes a U-shaped ergonomic handle, which makes movement easier even under heavy load.

3. Reinforced Structure for Industrial-Level Stability

Maintenance environments demand reliability. A tool rack must support heavy tools, resist corrosion, and withstand daily use.

This product is built using high-quality cold-rolled steel, known for its:

- Strong structural integrity

- Smooth surface

- Excellent durability

✔ 3.1 Reinforced Bottom Structure

A triangular steel reinforcement plate at the base greatly enhances stability.

Paired with enlarged screws, the bottom structure improves:

- Load-bearing capability

- Vibration resistance

- Overall lifespan

✔ 3.2 Seamless Connections

The board, uprights, and shelves fit with tight tolerances—no wobbling, no gaps, and no deformation.

This is crucial when storing heavy tools such as:

- Impact drivers

- Ratchets

- Steel tool sets

4. Human-Centered Design for Professional Use

✔ 4.1 Ergonomic Dual-Side U-Handle (Mobile Models)

When the rack needs to be repositioned:

- The U-shaped handle distributes force evenly

- Provides a comfortable grip

- Prevents hand fatigue

- Makes pushing or pulling smoother even when fully loaded

✔ 4.2 Rich Optional Accessories

A major advantage is the availability of different hooks and attachments.

Below is a categorized list:

Tool Hooks

- Six-section hook

- U-hook

- Sleeve hook

- Wrench holder

- Saw hook

- Single/dual angled hooks (50 mm / 100 mm)

Parts Bins

- No.1, No.2, No.4 back-hanging bins

- Combined modular bins

Perfect for fasteners, electrical parts, and small components.

Special Tool Holders

- Drill holder

- Wire frame

- Circular ring hook

These options make the rack adaptable to almost every industrial tool category.

5. Visual Management and Fast Access: Why Maintenance Teams Prefer It

Modern industrial environments emphasize:

- Lean 5S

- Faster response times

- Reduced downtime

- Clear locations for every tool

Single-sided tool storage racks directly support these goals.

single-sided tool storage rack Benefits Overview (Table Format)

| Feature | Benefit | Suitable For |

|---|---|---|

| Square-hole pegboard | Tools are visible and easy to reach | Mechanical tools, power tools |

| Louvered bin panel | Clear parts management | Fasteners, electronics |

| Mobile casters (optional) | Flexible workflows | Automotive repair, assembly line |

| Reinforced steel structure | Long-term reliability | Factories, warehouses |

| Modular accessories | Supports a full range of tools | Maintenance departments |

End Result

Maintenance staff can:

- Locate tools instantly

- Reduce unnecessary walking

- Keep workspaces tidy

- Improve repair response speed

- Increase overall productivity

This is precisely why maintenance supervisors and facility managers consistently prefer this storage solution.

Single-sided tool storage racks are the best choice because they are stable, work with a lot of different tools, and can be moved around easily. These racks have a dual pegboard system, are made of high-strength steel, and can be set up in many different ways. They satisfy the needs of professional maintenance teams.

They help technicians work faster, find tools faster, and keep the area clean and orderly, which is in line with modern 5S and Lean Management requirements. They can be utilized in automobile shops, industrial plants, or warehouses.

This solution is one of the best investments for any B2B buyer looking for tool storage that is long-lasting, configurable, and of industrial quality.