In high-velocity logistics and manufacturing, operational throughput is the definitive measure of success. As traditional warehouses transition into high-tech fulfillment hubs, legacy static tables have become a primary constraint on assembly and repair cycles. To meet escalating volume requirements, we are shifting toward a more agile infrastructure: Modular Workbenches with Integrated Tool Storage.

But why is this shift happening now? And how exactly does a piece of furniture become a “game-changer” for your bottom line? In this deep dive, we’ll explore how modularity and integrated storage transform chaotic workspaces into streamlined hubs of productivity.

The Evolution of the Industrial Workstation

For decades, a workbench was just a flat surface. If a worker needed a tool, they walked to a central cabinet. If they needed a specific screw, they searched through a disorganized bin across the room. In lean manufacturing terms, this is known as “Motion Waste.” Every step taken away from the workbench is a second of lost productivity.

Modern modular workbenches, such as those featuring L-shaped cantilever uprights, solve this by bringing the entire workshop to the worker. By integrating vertical tool storage and under-desk cabinetry, these stations minimize movement and maximize focus.

1. The Modular Advantage: L-Shaped Cantilever Uprights

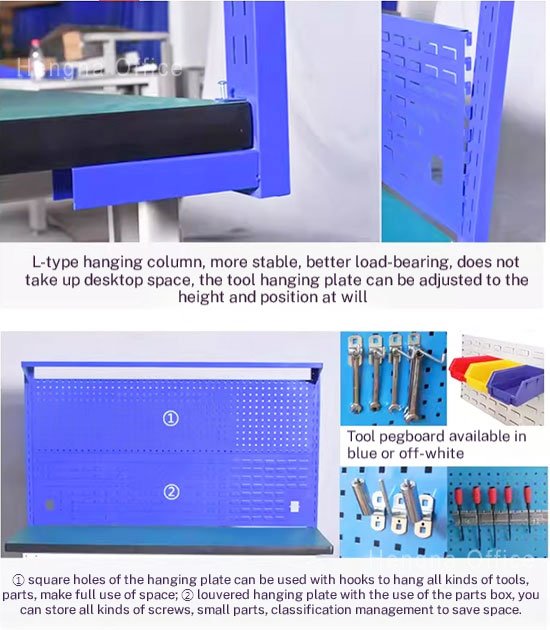

One of the most significant design breakthroughs in industrial furniture is the L-shaped cantilever upright system. Unlike traditional four-leg tables that can feel restrictive, these uprights offer a unique set of benefits:

- Stability Without Bulk: The L-shaped design provides a high load-bearing capacity while maintaining a sleek profile.

- Zero Table-Space Interference: Because the uprights are positioned at the rear, they do not consume valuable tabletop real estate. This allows for larger assembly projects to sit flat on the surface.

- Adjustability: These uprights serve as a “spine” for the workstation. Tool boards and shelves can be adjusted in height and position to suit the ergonomic needs of different workers.

2. Vertical Optimization: The Dual-Panel System

The space above the workbench is often wasted. A modular system utilizes this “vertical real estate” through a sophisticated dual-hanging panel system. As seen in professional setups, this usually involves two distinct types of panels:

① Square Hole Pegboards

These are the backbone of tool organization. The square hole pattern is designed to accommodate a variety of heavy-duty hooks and holders.

- Best for: Power drills, wrenches, hammers, and specialized calibrated tools.

- Benefit: Implements “Shadow Boarding,” where every tool has a visible, dedicated home, making it obvious if something is missing at the end of a shift.

② Louvered Panels

These panels are designed specifically to hold plastic parts bins

- Best for: Screws, bolts, washers, electronic components, and small spare parts.

- Benefit: Enables color-coded sorting. Workers can grab exactly what they need without rummaging through drawers, significantly speeding up assembly times.

3. Integrated Cabinetry: Everything in Arm’s Reach

The bottom half of a game-changing workbench is just as important as the top. High-volume warehouses benefit immensely from integrated drawer cabinets. By replacing standard table legs with heavy-duty drawer units, you gain:

- High-Capacity Storage: Large drawers can hold heavy mechanical parts or diagnostic equipment.

- Centralized Security: Most integrated cabinets feature a central locking system, ensuring that expensive specialized tools stay safe during off-shift hours.

- Improved Ergonomics: Drawers allow for “below-the-waist” storage of items that are used frequently but shouldn’t clutter the main work surface.

Comparison: Traditional vs. Modular Workbenches

| Feature | Traditional Static Bench | Modular Integrated Workbench |

| Storage Capacity | Minimal / Under-desk clutter | High / Organized vertical & cabinet storage |

| Tool Accessibility | High motion waste (walking to tools) | Zero motion waste (tools at arm’s length) |

| Flexibility | Fixed height/configuration | Adjustable height and modular add-ons |

| Durability | Varies (often basic steel) | Heavy-duty steel with polymer composite tops |

| Space Efficiency | Large footprint for separate storage | Compact, all-in-one footprint |

4. The Importance of the Surface: Thickened Composite Tabletops

The tabletop is the most abused part of any workbench. Whether you are dealing with heavy mechanical impacts or sensitive electronic components, the material matters.

Professional-grade benches often use High-Polymer Composite surfaces with high-strength plastic edging. These surfaces are designed to be:

- Impact Resistant: They won’t crack or dent under heavy loads.

- Chemical & Oil Resistant: Essential for automotive or industrial repair settings.

- Anti-Static (ESD) Capable: For electronics assembly, these surfaces can be treated to dissipate static electricity, protecting sensitive microchips from damage.

5. Lean Manufacturing and the 5S Methodology

Investing in modular workbenches is the fastest way to implement 5S (Sort, Set in order, Shine, Standardize, Sustain) in your warehouse.

- Sort & Set in Order: With dedicated hooks and bins, there is a place for everything.

- Standardize: When every workstation in your facility uses the same modular setup, workers can move between stations seamlessly without having to relearn where tools are located.

6. Procurement Considerations: Choosing the Right Supplier

When sourcing these workstations for your B2B needs—such as those from Juntuo (Hengna Office Furniture)—you should look for specific quality indicators:

- Steel Gauge: Ensure the frame is made of high-quality, cold-rolled steel for maximum longevity.

- Customization (OEM/ODM): Can the supplier provide different colors (like the classic blue and grey-white combo) or specific drawer configurations?

- Ease of Assembly: In a large-scale warehouse rollout, the time it takes to assemble the benches can impact your project timeline.

Conclusion: The ROI of a Better Bench

While a modular workbench with integrated storage has a higher upfront cost than a basic table, the Return on Investment (ROI) is realized through saved labor hours. If a modular bench saves a worker just 10 minutes of “searching and walking time” per day, it pays for itself in a matter of months.

By optimizing your workflow with L-shaped uprights, dual-panel hanging systems, and integrated cabinetry, you aren’t just buying furniture—you are buying a more efficient, more profitable warehouse.

Ready to Upgrade Your Warehouse Workflow?

At Juntuo (Hengna Office Furniture), we specialize in heavy-duty, modular solutions designed for the modern industrial market. From ESD-safe surfaces to custom-configured drawer cabinets, we help you build a workstation that works as hard as you do.

Would you like a custom quote for your facility or a digital catalog of our latest workbench models? Contact our professional team today.