In many industrial, commercial, and even some home – based workshop settings, the standard off – the – shelf heavy – duty workbenches might not fully meet the unique requirements of the users. This raises the question: can heavy – duty workbenches be customized? The answer is a resounding yes, and here’s how.

1. Understanding the Feasibility of Customization

Heavy – duty workbenches are highly customizable due to the diverse range of materials and manufacturing techniques available. Manufacturers are often equipped to adapt the design, dimensions, and features of the workbench to suit specific user needs. This is because the construction of these workbenches typically involves modular components or processes that can be adjusted.

2. Customization in Dimensions

One of the most common ways to customize a heavy – duty workbench is by adjusting its dimensions. If you have a limited workspace or require a specific size to fit your workflow, you can request a customized length, width, and height. For example, in a narrow industrial aisle, a custom – sized workbench with a reduced width but sufficient length can be designed. This ensures that the workbench not only fits the space but also provides enough surface area for work operations.

3. Material Selection Customization

The materials used in the construction of a heavy – duty workbench can also be customized. Steel is a popular base material, but different grades of steel can be chosen based on the required strength and durability. For extremely heavy – duty applications, high – grade alloy steels might be preferred. Additionally, the workbench top can be customized. Options include stainless – steel tops for corrosion – resistance in chemical – handling environments, or composite tops that offer a balance of strength and affordability.

4. Feature – Based Customization

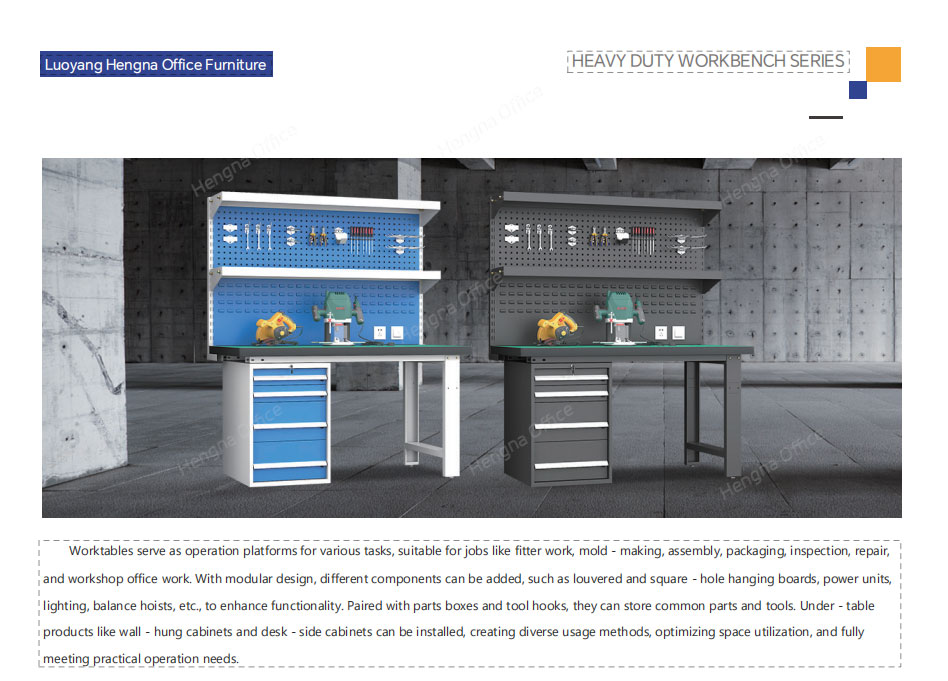

- Storage Features: Workbenches can be customized with various storage options. Drawers of different sizes can be added, some with heavy – duty slides to hold large and heavy tools. Shelves can be installed, either open for easy access or enclosed with doors for storing sensitive or valuable items. For example, a machine shop might require a workbench with deep drawers for storing machining tools and a closed – door cabinet for keeping lubricants and solvents.

- Integrated Tools and Accessories: Another aspect of feature – based customization is the integration of tools and accessories. Some users might need a built – in vice for clamping workpieces, or a power strip with multiple outlets for powering electrical tools. Workbenches can also be customized with tool – holding systems, such as pegboards or magnetic strips, to keep tools organized and easily accessible.

5. The Customization Process

- Initial Consultation: The customization process usually begins with an in – depth consultation between the user and the manufacturer. During this stage, the user explains their specific requirements, such as the intended use of the workbench, the available space, and any special features they desire.

- Design Phase: Based on the information gathered, the manufacturer’s design team creates a detailed design plan. This plan includes 2D or 3D drawings that show the customized workbench from different angles, highlighting all the customized elements. The user has the opportunity to review and suggest any changes to the design at this stage.

- Manufacturing and Assembly: Once the design is approved, the manufacturing process begins. The manufacturer sources the required materials and starts fabricating the customized components. After fabrication, the workbench is assembled, and quality checks are performed to ensure that it meets all the specified requirements.

- Delivery and Installation: Finally, the customized heavy – duty workbench is delivered to the user’s location. Some manufacturers also offer installation services to ensure that the workbench is properly set up and ready for use.

In conclusion, heavy – duty workbenches offer a high degree of customization potential. By understanding the different aspects of customization and the process involved, users can get a workbench that perfectly suits their needs.