When it comes to selecting a heavy – duty tool cabinet, several crucial factors demand your attention. This article explores key considerations like storage capacity, durability, and locking mechanisms to help you make an informed choice.

In the world of workshops, garages, and industrial settings, a heavy – duty tool cabinet is not just a piece of furniture; it’s an essential asset. It serves as the central storage hub for your valuable tools, keeping them organized, protected, and easily accessible. However, with a plethora of options available in the market, choosing the right one can be a daunting task. Here are some Key Considerations in Choosing Heavy – duty Tool Cabinet.

Storage Capacity

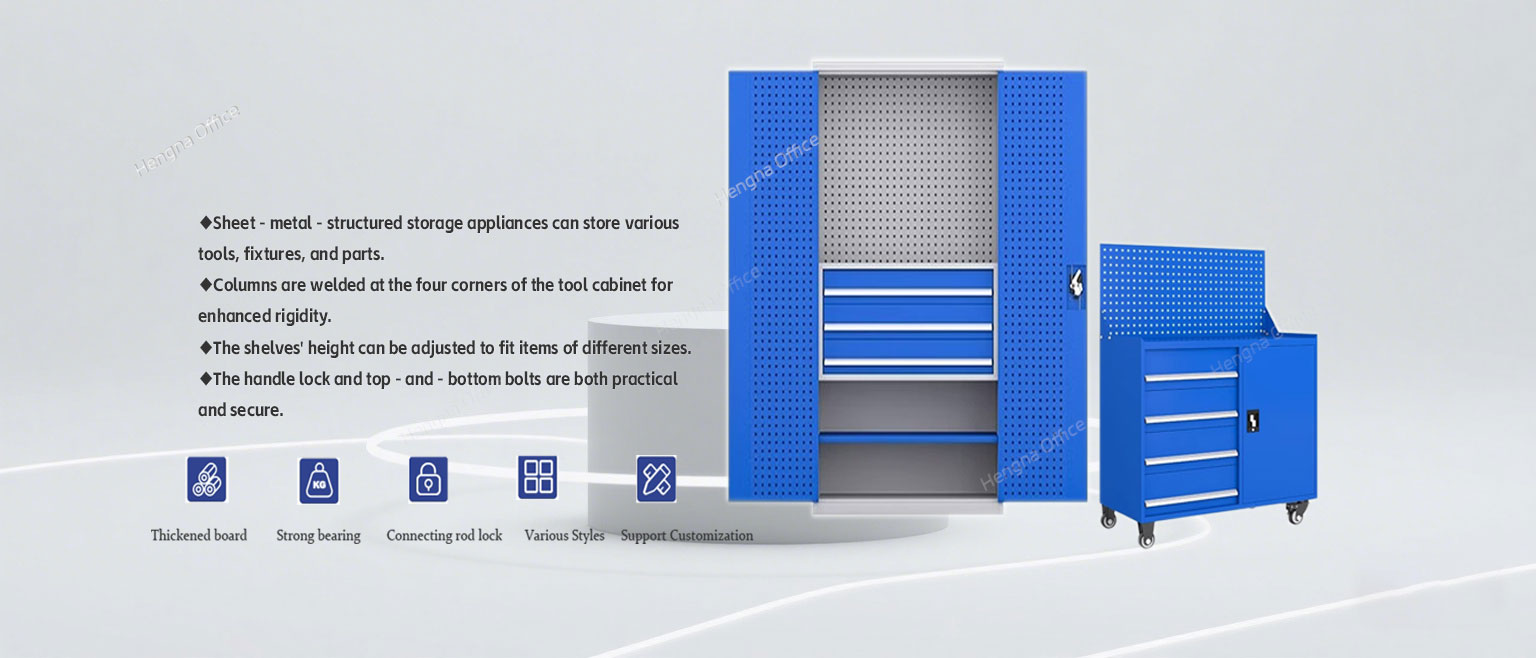

The first and foremost factor to consider is storage capacity. Think about the types and quantity of tools you own or plan to acquire in the future. If you’re a professional mechanic with an extensive collection of wrenches, sockets, and power tools, you’ll need a tool cabinet with multiple drawers of varying sizes. Look for cabinets that offer deep drawers for larger items like power drills and saws, and shallow drawers for smaller hand tools such as screwdrivers and pliers. Some heavy – duty tool cabinets also come with additional storage features like adjustable shelves, pegboards, or side – mounted tool holders. These extra elements can significantly expand the cabinet’s storage capabilities, allowing you to neatly stow away everything from tool accessories to safety equipment.

Durability

Heavy – duty tool cabinets are expected to withstand the rigors of a busy work environment. Therefore, durability is non – negotiable. The cabinet should be constructed from high – quality materials. Steel is a popular choice as it offers excellent strength and resistance to wear and tear. Check the thickness of the steel used; a thicker gauge steel will generally be more robust and less likely to dent or deform under the weight of your tools. Additionally, pay attention to the quality of the welds. Strong, well – made welds ensure that the cabinet’s structure remains intact even when subjected to constant use and movement. Look for cabinets that are powder – coated or painted, as this finish not only provides an aesthetic appeal but also protects the steel from rust and corrosion, extending the cabinet’s lifespan.

Locking Mechanisms

The safety and security of your tools are of utmost importance. A reliable locking mechanism is essential to prevent unauthorized access to your valuable equipment. Many heavy – duty tool cabinets come with key – operated locks, which are a standard and effective way to keep your tools secure. However, some modern cabinets also offer more advanced locking options such as combination locks or electronic locks. These can be more convenient, especially if you’re prone to losing keys. When evaluating the locking mechanism, ensure that it is robust and difficult to break or bypass. Additionally, consider cabinets that have locking drawers or compartments, providing an extra layer of security for your most valuable or sensitive tools.

Mobility

If you need to move your tool cabinet around your workshop or job site, mobility is a key consideration. Some heavy – duty tool cabinets are equipped with wheels or casters. These should be made of high – quality materials and be able to support the weight of the fully – loaded cabinet. Look for wheels that have brakes, allowing you to keep the cabinet stationary when needed. Additionally, consider the maneuverability of the wheels. Swivel casters at the front of the cabinet can make it easier to turn and navigate through tight spaces. However, if the cabinet will be used in an area with uneven floors, larger, more durable wheels may be a better option to ensure smooth movement.

Drawer Organization

Efficient drawer organization can make a world of difference in how quickly you can find the tools you need. Some heavy – duty tool cabinets come with pre – designed drawer inserts or dividers. These can be customized to fit specific types of tools, keeping them organized and preventing them from shifting around during use. For example, a drawer insert with compartments of different sizes can be perfect for storing a variety of sockets. Additionally, consider drawers with ball – bearing slides. These slides provide a smooth and quiet operation, even when the drawers are fully loaded. They also help to extend the lifespan of the drawers by reducing wear and tear.

In conclusion, choosing the right heavy – duty tool cabinet requires careful consideration of these key factors. By taking the time to assess your storage needs, prioritize durability, security, mobility, and drawer organization, you can invest in a tool cabinet that will serve you well for years to come.